CBR Test Results ExplainedWhat is CBR Testing?

The California Bearing Ratio (CBR) test is a key method in civil engineering to test the strength of subgrade soils. Developed by the California State Highway Department in the 1930s, this has become a global standard to test the bearing capacity of soils for road and foundation construction. CBR testing gives you the strength of the soil, and you use that to make decisions on pavement design, subgrade surface preparation, and foundation support. In this article, we will go through CBR test results, how they are calculated, and what they mean in construction projects.

What is the California Bearing Ratio (CBR) Test?

The CBR test measures the penetration resistance of a soil sample by comparing it to a standard material. The ratio is expressed as a percentage and is the strength of the subgrade soil relative to that standard.

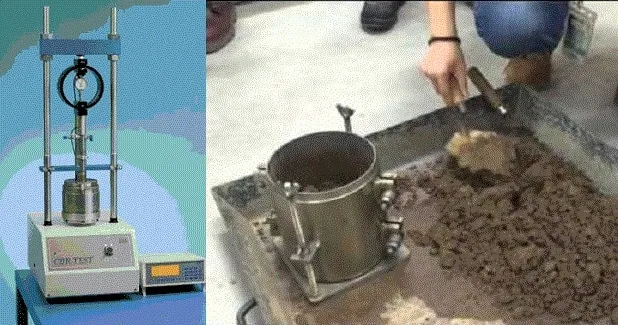

To conduct a CBR test, a cylindrical plunger is applied to a soil sample at a steady rate. The force required to achieve specific depths of penetration is recorded and then used to calculate the CBR value. This penetration test was developed to simulate the stresses that subgrade soils experience in roads, so that engineers can evaluate the load-bearing capacity of soils before construction.

CBR Test Procedure

A standard CBR test follows a specific procedure:

Sample Preparation: The soil sample is placed in a CBR mould and compacted to the same density as field conditions.

Moisture Control: Moisture affects soil strength. The soil may be soaked before testing to simulate wet subgrade soil conditions.

Penetration and Load: The plunger applies incremental load, and the force required to achieve penetration depths is measured. Usually, these are set at 2.5mm and 5mm depths, the same as equal penetration in standard crushed rock.

CBR Value: The force at each penetration depth is compared to a standard load. The higher the CBR value, the stronger the soil.

Typical CBR Values and What They Mean

CBR values range from low to high. Interpreting these values helps engineers to estimate the design subgrade surface modulus.

Typical CBR value interpretation:

Less than 5%: Weak soil with low load-bearing capacity; may need subgrade replacement.

5-10%: Moderate soil strength; may support light traffic with reinforcement.

10-30%: Medium strength, suitable for most road subbases with proper design.

30-80%: High strength, often found in dense granular materials; suitable for heavy traffic.

80-100%: Very high strength, typical in fully compacted, high-quality granular material.

CBR Test Results in Construction Design

CBR test results are used in pavement and foundation design. CBR test results tell you the strength of the soil, which directly affects the pavement thickness and type of materials required.

Other Tests and Complementary Tests

While the CBR test is widely used, it is sometimes complemented by other test methods that provide more information on subgrade conditions. These are:

Plate Load Test: Measures surface stiffness and estimates subgrade surface modulus by applying load to a larger plate.

Incremental Plate Load Test: An incremental load test to observe deformation.

Dynamic Cone Penetrometer (DCP) Test: A rapid test to measure in-situ penetration resistance to calculate equivalent CBR values in variable subgrade soils.

Light Weight Deflectometer (LWD): Measures subgrade surface stiffness for construction purposes.

Each test can validate or complement CBR test results.

Factors Affecting CBR Test

Several factors affect CBR test results, each providing geotechnical engineers with important information on subgrade soil conditions:

Moisture Content: High moisture reduces soil strength, resulting in lower CBR values.

Soil Density and Compaction: Well-compacted soil yields higher CBR values.

Soil Type and Maximum Particle Size: Fine-grained soil produces lower CBR values, while coarse materials produce higher values.

Testing Conditions: In-situ tests may vary due to local conditions, whereas laboratory tests are controlled.

How to Improve Low CBR Values

When CBR test results are below the minimum CBR requirement for a project, engineers can use the following methods to improve soil strength:

Soil Stabilisation: Adding lime or cement can increase soil strength and CBR values.

Geotextiles and Geogrids: These distribute loads across subgrade soil and reduce the need for thick base layers.

Compaction: Compacting the soil to remove air voids can increase CBR values and create a stable base for construction.

CBR Test Results in Foundation Design

For subgrade soil that requires a stable base, CBR tests with different penetration depths can help engineers evaluate the bearing capacity. The results can also guide the use of other in-situ tests like the plate bearing test.

Calculating Subgrade Surface Modulus from CBR Values

CBR values can be used to estimate subgrade surface modulus, a parameter that represents the stiffness and load-bearing capacity of the soil.

CBR Test and Sample Preparation

Geotechnical engineers perform undisturbed and remoulded tests, with samples prepared in a CBR mould that reflects field density. Control of sample moisture content and maximum particle size ensures the CBR value represents the actual performance of the soil.

CBR Test Results for Design and Environmental Consideration

By knowing the subgrade strength, engineers can optimise material use, reduce the environmental impact of excessive excavation or material sourcing, and, by interpreting CBR values, apply subgrade improvement techniques precisely to minimise soil disturbance and preserve the natural ecosystem.

Summary

The California Bearing Ratio test is fundamental in civil engineering, providing important information on subgrade strength and bearing capacity. By considering moisture, density, compaction, and other testing methods, engineers obtain reliable CBR values to guide pavement design, foundation support, and subgrade improvement.

With other tests like the plate bearing test and DCP, civil engineers have a complete set of tools to ensure project success, making CBR values essential in planning and execution.