Revamping Industrial Heat Mechanisms: The Manifesto of NIIFT for a Sustainable TomorrowIntroduction

Sculpting the Future with NIIFT’s Steam Generators

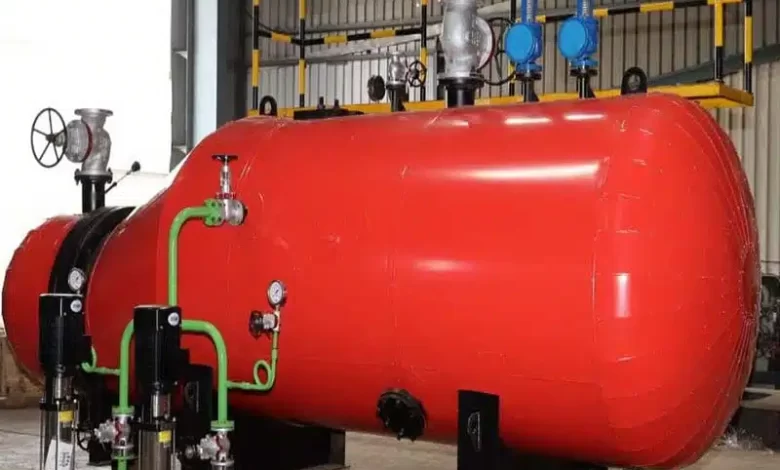

In the ever-evolving sphere of industrial thermodynamics, NIIFT emerges as a beacon of innovation and environmental consciousness with its advanced commercial steam generators. These units, envisioned for tomorrow’s needs, blend pioneering technological advancements to cater to the dynamic requirements of industries across Thailand and Southeast Asia. This narrative delves into the distinctive attributes and innovative developments that position NIIFT as a vanguard in the realm of steam generators.

Distinctive Elements of NIIFT’s Avant-Garde Commercial Steam Generators

Modular Configuration for Enhanced Flexibility

NIIFT’s steam generators boast a modular design, promoting unparalleled flexibility in both installation and function. This architecture enables customizable solutions that align perfectly with specific industrial demands, significantly bolstering system efficiency and versatility—essential for businesses dependent on robust heating solutions.

Remote Supervision for Augmented Efficiency

Armed with sophisticated remote surveillance technology, NIIFT’s generators permit real-time management of operations. This feature ensures peak performance and energy efficiency by enabling precise adjustments and forward-thinking diagnostics within the system, markedly diminishing operational interruptions.

Commitment to Emissions Reduction for Sustainable Operations

Sustainability is a core tenet of NIIFT, particularly manifest in their steam generator designs. These units integrate advanced emission curtailment technologies that lessen environmental impact, adhering to both international and local ecological standards for a more sustainable future.

How NIIFT Amplifies Energy Efficiency within Their Steam Generators

Cutting-edge Combustion Techniques

At the core of NIIFT’s steam generators resides an advanced combustion methodology that optimizes energy consumption and output per fuel unit. This technique ensures the generators function at supreme efficiency, minimizing both operational expenses and ecological footprints—a pivotal trait for contemporary industrial heating systems.

Superior Heat Exchangers for Optimal Thermal Transfer

Employing high-efficiency heat exchangers, NIIFT enhances thermal transfer while curbing energy wastage within their generator frameworks. These components are crucial in sustaining the efficacy of the steam creation process, ensuring maximal energy utilization for industrial applications.

Elevating NIIFT’s Commercial Steam Generators in the Industrial Arena

Automation for Streamlined Operations

NIIFT’s steam generators incorporate automation technologies that simplify myriad processes, from fuel logistics to emissions management. This integration eases the complexity of generator operations, heightening safety and dependability.

Compact and Modular Build for Spatial Economy

The streamlined and modular construct of NIIFT’s generators is ideally suited for sectors with spatial constraints. This design allows for seamless incorporation into existing frameworks without the need for extensive site adaptations.

Why is Remote Monitoring Indispensable in Commercial Steam Generators?

Real-Time Operational Monitoring

Remote monitoring represents a pivotal advancement in commercial steam generators. Providing up-to-the-minute performance analytics, NIIFT empowers operators to enact informed strategies that refine operational efficiency and avert potential disruptions.

Proactive Maintenance for Enhanced Durability

With remote monitoring, maintenance shifts from a reactive to a proactive strategy. This approach not only extends the lifespan of the generators but also ensures they operate at utmost efficiency, reducing both unexpected downtime and maintenance expenditures.

NIIFT’s Approach to Environmental Challenges with Their Steam Generators

Techniques for NOx Emission Abatement

In tackling environmental degradation, NIIFT meticulously designs its generators to incorporate progressive emission reduction strategies, focusing on diminishing nitrogen oxide (NOx) emissions. Recognized as major atmospheric contaminants, nitrogen oxides are implicated in various health hazards and environmental issues. NIIFT’s advanced combustion control techniques and selective catalytic reduction (SCR) systems convert detrimental nitrogen oxides into benign nitrogen and water vapor, a process catalyzed within the generator confines, ensuring cleaner emissions.

Furthermore, NIIFT’s generators feature low-NOx burners, tailored to mitigate pollutant genesis by optimizing the combustion environment to curtail oxygen presence, thus reducing the emergence of nitrogen oxides. This approach not only meets but often exceeds stringent environmental mandates.

Advocating Biofuel Use for Environmentally Friendly Heat Generation

NIIFT fervently champions the adoption of biofuels as a sustainable and environmentally benign energy source for their steam generators. Derived from organic sources, biofuels offer a greener alternative to conventional fossil fuels, thereby reducing emissions and aligning with global sustainable energy initiatives.

Conclusion: Pioneering Industrial Boiler Innovation

NIIFT stands at the forefront of the steam boiler industry, steering progress and ecological responsibility through innovative boiler designs. Their commitment to energy efficiency, environmental preservation, and advanced technology solidifies their role as a leader in commercial heating and industrial boiler solutions in Thailand and beyond.

About NIIFT

NIIFT (Notable Industrial Innovations for Tomorrow) excels in top-tier energy solutions across Southeast Asia, focusing on industrial boiler systems. Committed to innovation and ecological conservation, NIIFT aims to deliver high-efficiency, eco-friendly heating technologies that enable industrial prosperity while safeguarding our planet.